The thin air around us can help us reduce the cost of fertilizers to produce ammonia from the air with the new device. New process to produce ammonia from the air can help the farmers produce fertilizers from the air. This does not need any further heating, electricity, or any other process.

The university of Stanford in collaboration with King Fahd University of Petroleum and Minerals in Saudi Arabia developed a prototype that can fetch the droplets from the air and convert it to Ammonia without using additional electricity or radiation.

This will help reduce the carbon emission by 1% and save global energy costs by 2% that are used to for addition radiation or heat to produce Ammonia. It is mostly the gas that used to heat up to produce Ammonia.

Ammonia Production

Ammonia is the second most produce chemical in the world which consumes around 2% of the global energy and 5% of gas usage around the globe. 183 million metric tons of Ammonia is produced around the world annually.

The new method developed by university of Stanford in collaboration with King Fahd University of Petroleum and Minerals in Saudi Arabia can help us to produce (NH3) from air and save billions along with deduction in the carbon emissions.

(NH3) is used for various purposes. it is used to transfer energy from one place to another. Ammonia is also used to produce fertilizers and for synthesis of the other chemicals. It accounts for 2% of the global energy usage and 5% of for the global gas usage.

Get Rid of Bird of Paradise Leaves Curling with proven strategies

Does Potting Soil Go Bad: study Shelf Life, Storage, and Quality

Plants that look like marijuana: 10 amazing facts, ways to foster

This will help farmers produce Ammonia from the air with the help of the new device which will reduce carbon emissions, replace the century old method of the chemical production which involves high pressures to combine hydrogen and nitrogen.

This research has been performed on-site not in the lab. The farmers now can use the device to produce the chemical from thin air which operates on room temperatures or according the atmosphere.

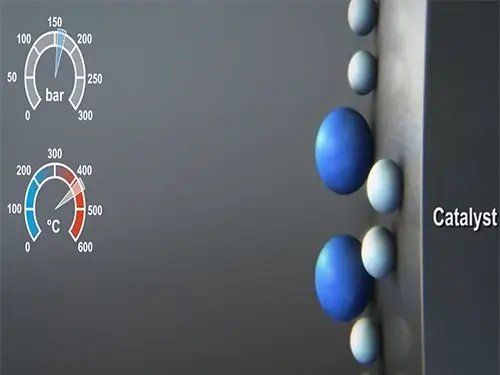

They have investigated various factors that can affect the production of Ammonia with the new device without the high pressures and to reduce the carbon emissions and to save 2% of the global energy.

They have investigated air pressures, water droplets size, wind speed, humidity, and salt concentration.

After complete investigation of the environmental factors that can affect the production of Ammonia (NH3), such as humidity, acidity, and wind speed, the scientists of the Stanford University combined iron oxide and an acid polymer containing fluorine and sulfur that can help produce the chemical in a clean and efficient way by utilizing ambient air to extract nitrogen and hydrogen from water vapor.

scientists and researchers were looking for some affective and efficient ways to produce Ammonia by using alternate ways to Haber-Bosch process that require high pressures and a lot of energy and they finally created the device that can operate on the room temperatures to create the chemical from the air.

The water contain a lot of energy that can save a lot of resources for the humans and reduce emissions to keep sustainable farming intact. The droplets in the air are taken and converted into Ammonia with the help of the this device.

“This breakthrough allows us to harness the nitrogen in our air and produce ammonia sustainably,” “It’s a significant step toward a decentralized and eco-friendly approach to agriculture.”

Richard Zare professor of chemistry at the Stanford School of Humanities

This innovate approach toward clean energy usage and production of chemical will help us reduce carbon emissions and produce sustainable agriculture with lower energy costs.

This device will be market-ready in two years while the researchers are trying to increase the chemical production by making large mesh systems according to study co-author Chanbasha Basheer of King Fahd University of Petroleum and Minerals

3 thoughts on “Ammonia air producing device can save 2% of Carbon Emissions”